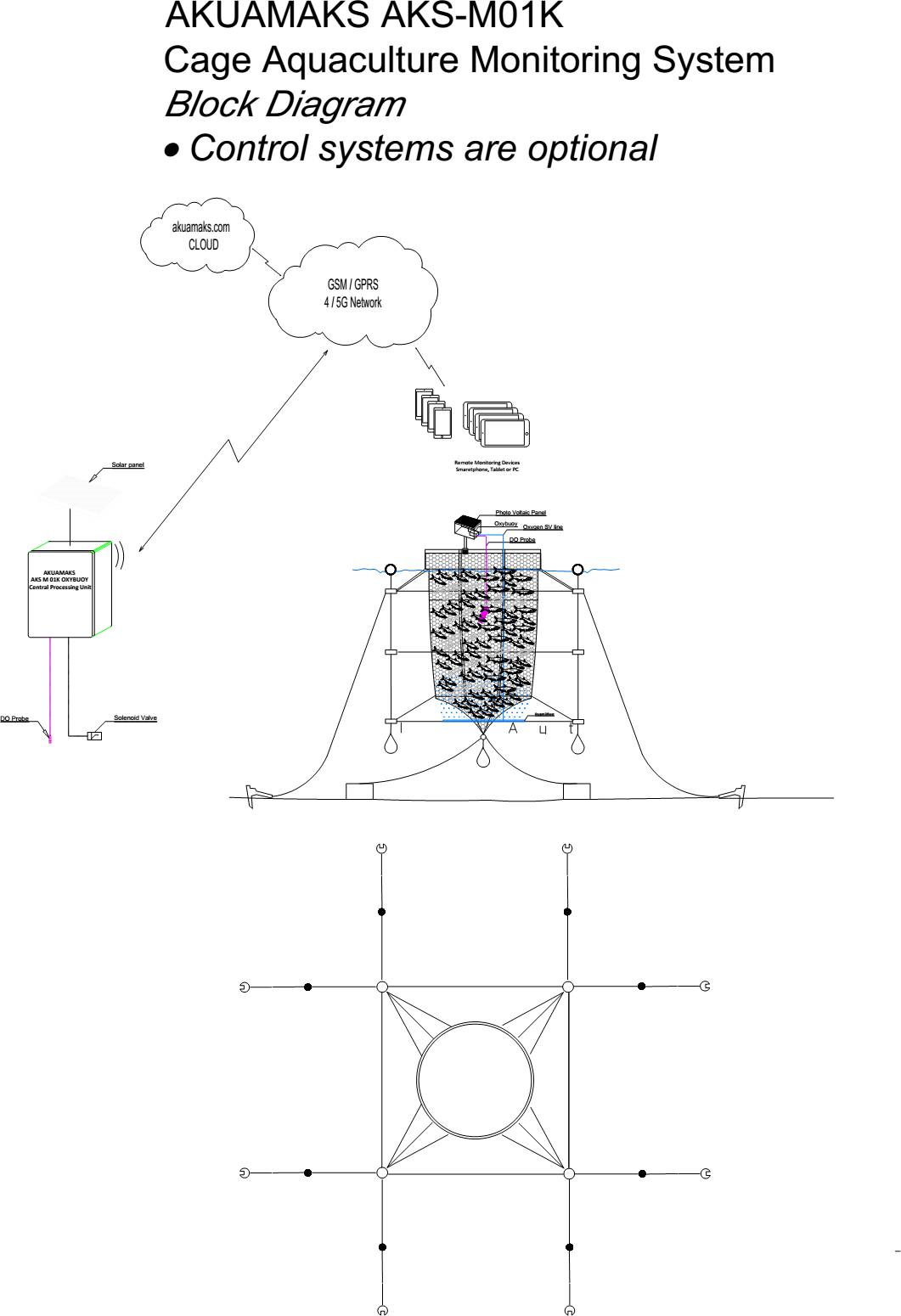

Our monitoring systems are connected to the upper pipe of the cage in cage aquaculture farms in dams, rivers, seas, and oceans receive their energy from the solar panel on it, are resistant to all weather conditions, and operate 24/7. In this system, the electronic processor inside the body with the IP68 protection class sends the data from the optical probe to the cloud regularly, approximately every ten minutes.

With the GPS module, the satellite coordinates where the system is located are sent to the cloud with measurement data such as latitude and longitude data.

Since they work with solar energy, these systems, which can be easily mounted on the cage upper pipe without needing another energy source or power cabling, perform their duties in all weather conditions, without being dependent on humans.

Thanks to its software, optimum measurement values, lower and upper alarm limit values can be programmed, remote calibration and system control can be performed via the cloud.

Standard dissolved oxygen, temperature, and saturation values are measured instantly and sent to the electronic processor with the optical probe lowered into or outside the cage from the control unit mounted on the cage upper pipe. Throughout the season, measurements are made at the same or different depths depending on the probe distance, according to the evaluation of the cage facility management team, and analyzes are made for emergency management and applications, especially the transfer period plan, fish stock density, feeding plan, harvest plan.

Our monitoring systems are equipped with a direct transmission module in cage aquaculture farms. In these types of installations, the fact that they can be connected to the Internet via a mobile phone on the cages to be measured indicates that there is enough signal for data flow. Measurements made on the cage 10 minutes to the central server over the data line at intervals. All measurements are recorded on the central server.

There is a separate file for all systems in the central server. All measurement results can be viewed up-to-date as soon as they are received, as well as recorded. The records can only be accessed by authorized personnel by using a username and a password.

All data can be accessed via tablets, mobile phones, and computers anywhere on the globe with an internet connection. The results can be displayed either graphically or as an Excel spreadsheet, instantly, or by selecting a specific time period.

The module, easily assembled with only 4 bolts on the upper pipe of the cage, meets the needs of the battery in the waterproof IP 68 housing, which is supplied with the required solar panel.

Mounting on the module, the next-generation optical technology probe has a cable length of 10 meters. It can be lowered from the side surface of the cage to the deep side, and from the midpoint, it can provide access to the deepness of the level that fishes are fed. Thus, the dissolved oxygen, temperature and saturation measurements at the depth are transferred to instantaneous results.

Recently, cage oxygen control systems have been developed against sudden changes in oxygen decrease and related risks in inland waters and seas. Oxygenation equipment placed under the cage is fed with oxygen or ventilation lines, as in terrestrial systems, and when the optimum value is measured, it automatically acts as oxygenation within the cage, thanks to measurement tracking, recording and control systems.

SENSORS

Measuring sensors that are resistant to corrosion and equipped with optical technology are used. These sensors transmit the measurement results to the main processor. In this technology, which is resistant to severe conditions, the sensors work efficiently for many years with regular control and sensor cleaning. There is no need for the membrane and solution that are required for the galvanic probes. As with galvanic probes, there is no risk of calibration deviation due to membrane puncture and solution depletion.

DATA TRANSMISSION

Software and hardware have been developed that allow instant tracking of measurement results from sensors at the local cage via transmission lines, instant tracking via the cloud, emergency management, access to historical records and alarm situations, graphical analysis, and data recording output. In these systems, unlike hand-held measuring devices, there are no disadvantages such as calibration problems, the need for personnel use, dependence on meteorological conditions and the inability to make measurements in bad weather conditions. It is a technology that is not dependent on humans, continuously measures in all weather conditions and transmits the results, thus enabling a traceable farming system.

ANALYZING CURRENT AND HISTORICAL DATA - EVALUATION

It allows monitoring of instantaneous values and control of changing status. Stock loss, feed loss can be prevented, and operating losses can be prevented. Data control is provided on strategically important issues such as production plan, oxygen and consumable feed consumption, and transfer planning.